Detailed information and operation method can be obtained by email

Email: kxbg365@qq.com

WeChat:czzhouhui

Functional features:

1. The utility model can scrape off the excess length of the pipe orifice and clear the welding seam, and the utility model has multiple functions;

2. Pneumatic locking and positioning, safe and fast;

3. Push rod feed and retract, fast and convenient;

4. Mechanical cold cutting, will not damage the pipe material, just a few seconds to complete a flat mouth;

5. The machine has long service life, low cost and high efficiency;

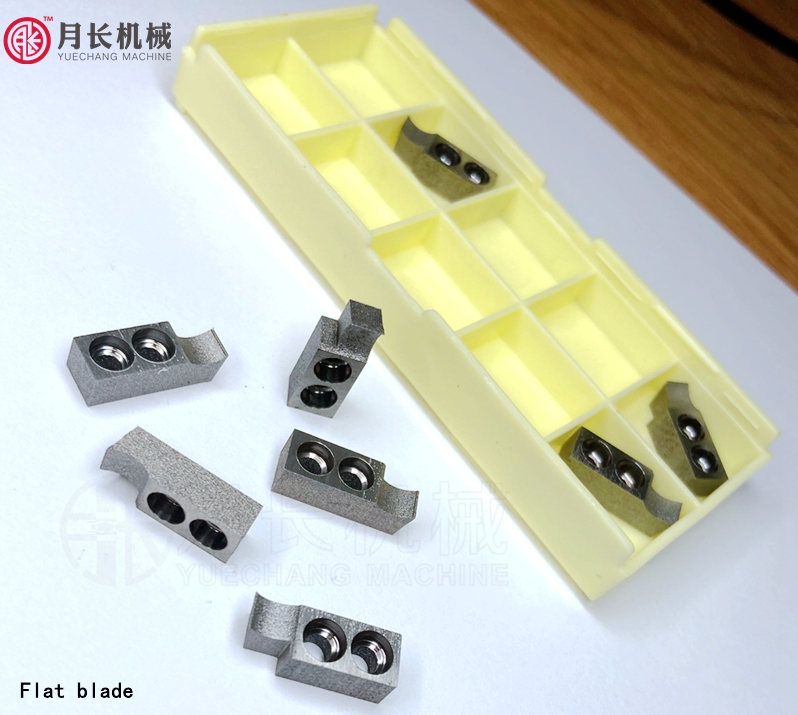

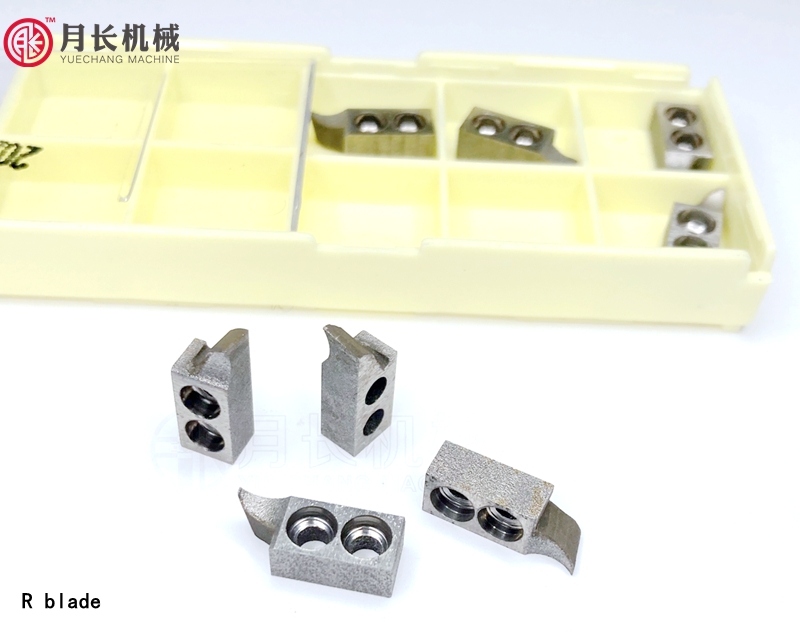

6. According to the characteristics of nozzle, reasonable tool holder and cutter are designed;

7. Safe and comfortable ergonomic design, the use of balance principle, reduce the burden of operation;

8. The small and compact cutter head can adjust the length at will to control the length of the nozzle;

9. Suitable for materials including carbon steel, stainless steel, titanium, etc;

10. It is small in size and can be used in different positions. It is portable and flexible;

Application:

1. Pipe orifice leveling; 2. Quick chamfering; 3. Remove the weld; 4. Pipe mouth beveling

The machine has the above four functions at the same time.

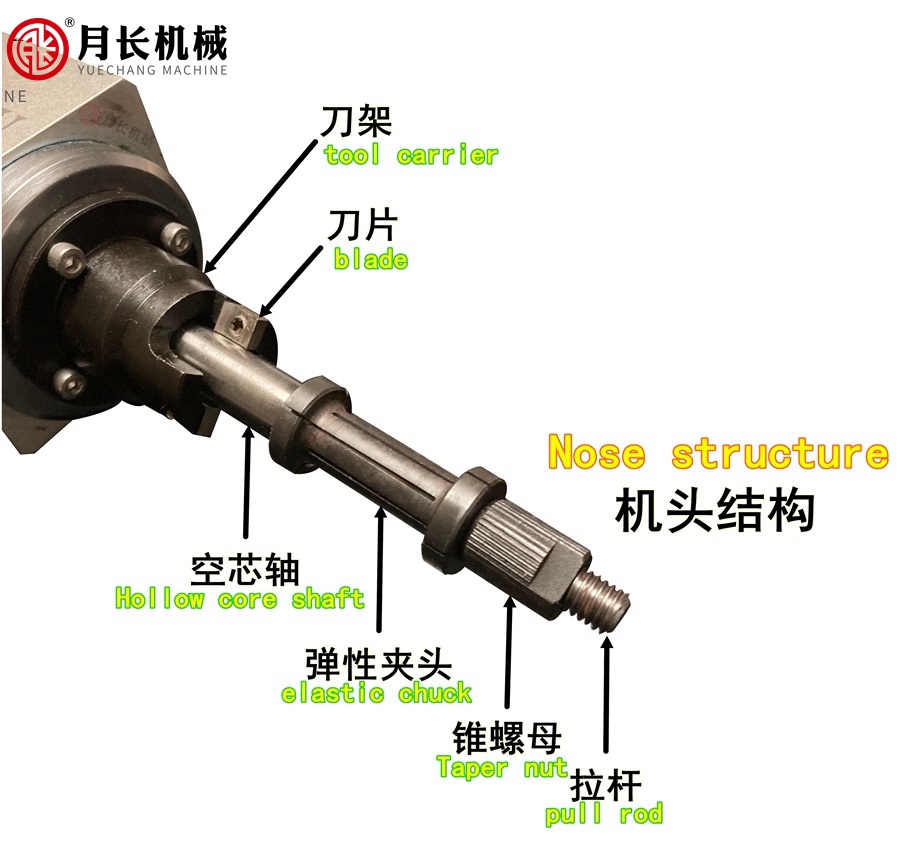

Nose structure:

Safety precautions:

1. Before use, please read the safety operation instructions carefully, and use the tools according to the instructions of the operation contents to ensure safety in use.

2. This tool is forbidden to be used in the places with explosion risk.

3. It is strictly prohibited to use gas other than air as a gas source to use tools to avoid the danger of explosion.

4. When tools are not used, parts are replaced or maintenance is carried out, please turn off the air source and unplug the connector between tools and air source.

5. Tools and accessories are not allowed to be changed at will. If different parts or parts not manufactured by our company are used, we will not be responsible for the warranty.

6. When operating tools, maintenance tools or replacing tool accessories, please wear impact resistant eye masks and masks at all times. Even small projectiles may harm eyes.

7. High volume will cause hearing damage. Users should wear standard earmuffs according to the regulations of various regions to protect users' safety.

8. Please do not directly contact the rotating transmission shaft and accessories to avoid injury, and wear gloves to protect your hands.

Air supply:

1. The winding of air compression pipeline will cause serious danger. Please check the air compression pipeline at any time and place it in an appropriate position.

2. All tools, fittings and air compression pipelines must meet the requirements of air pressure and volume.

3. The air used for supplying tools must be clean and dry. The moisture in the air will cause rust and damage to the metal inside the tools.

4. When operating tools, the maximum pressure at the air inlet shall not exceed 90psi (7kg/cm2).

5. The inner diameter of the whole compressed air supply pipeline, including the connector, shall not be less than 12mm, otherwise the air flow will be affected, which will lead to the inability of the flat end machine to finally waste the blade.

Precautions for equipment operation:

1. Before ventilation, keep the top tightening nut in a loose state to prevent the elastic chuck from being in an empty expansion state after ventilation, so that the chuck is damaged. Before or after using the tool, take down the elastic positioning chuck in time to avoid damage to the elastic positioning chuck caused by cylinder action.

2. Each pipe specification corresponds to one elastic positioning chuck. Please select the appropriate elastic positioning chuck.

3. After wiping into the nozzle for positioning, it should be noted that there is a gap of more than 1 mm between the nozzle and the blade to avoid damage to the blade and equipment due to instantaneous rotation.

4. The air pipe and connector configured for this machine or the air pipe and connector of the same specification must be selected to avoid different speeds caused by insufficient air flow.

5. When feeding, if the pipe end is uneven, please feed slowly. After the blade is fully contacted with the pipe orifice, it can be pushed forward quickly, otherwise it will cause the knife collision caused by the uneven pipe end. 6. If the equipment shakes violently during the feeding process, please slow down the feeding speed in time and feed after the nozzle is flat.